Latest news

-

NOBLE Participated in the COSMOPROF ASIA HONGKONG

11-22, 2023 -

NOBLE Obtained Three Important Certificates Includ

11-08, 2023 -

NOBLE Successfully Passed the Evaluation of “Innov

11-07, 2023 -

NOBLE Won the Title of "Innovative Small and

11-06, 2023

What Is Sheet Metal Fabrication? A Guide To Sheet Metal Fabrication Processes: Material&Finishing

Contents

[]

- 1.What is Sheet Metal Fabrication?

- 2.How Does Sheet Metal Fabrication Work?

- 3.Sheet Metal Prototyping to Production

- 4.Sheet Metal Fabrication Standards

- 5.Common Types of Sheet Metal Fabrication Processes

- 6.Finishing Options for Sheet Metal Fabrication

- 7.Material Selection for Sheet Metal Fabrication

- 8.Major Types of Sheet Metal

- 9.Benefits of Sheet Metal Fabrication

- 10.Applications of Sheet Metal Fabrication

- 11.Why choose NOBLE Custom Sheet Metal Fabrication?

- 12.Sheet Metal Fabrication FAQs

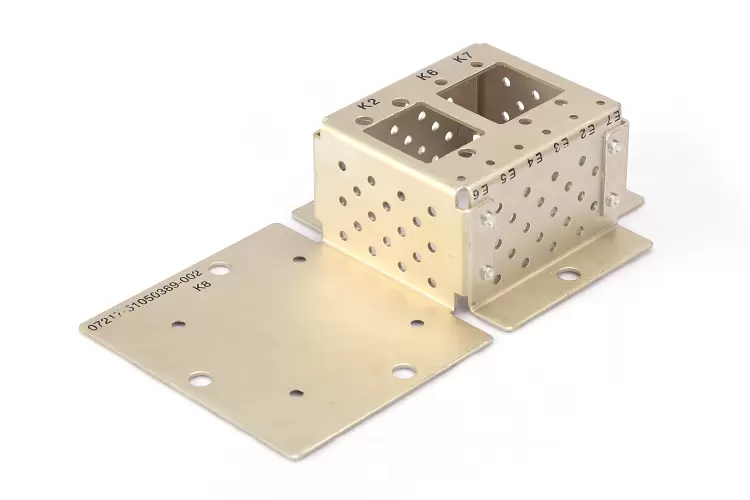

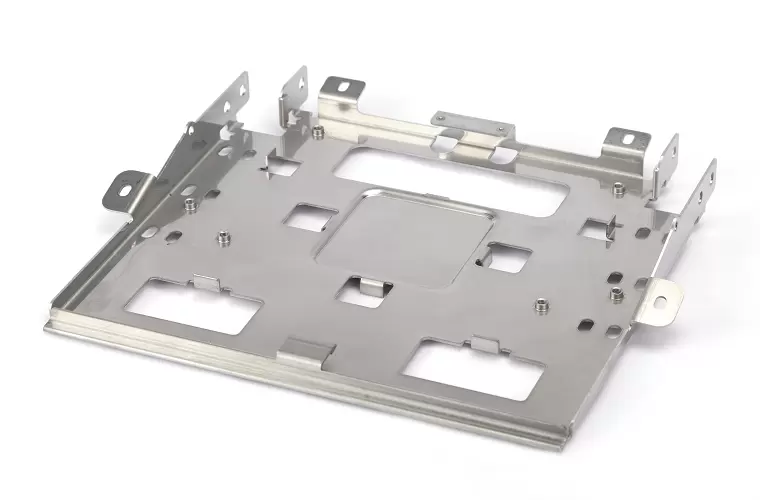

Sheet metal fabrication is the process of cutting and shaping flat sheets of metal into finished products. It is widely used in robotics automotive, aerospace, medical, construction, and electronics. Its materials are commonly used steel, aluminum, copper, brass, etc. And this technology can deal with various thicknesses of sheet metal, ranging from thin gauges used for creating electronics components, to thicker gauges used in construction and automotive applications. Common steps used in sheet metal fabrication are Bending, Cutting, Punching, and Welding. In order to cut the sheet metal into the desired shape and size. Various cutting tools could be adapted, including shears, lasers, and plasma cutters. And once the sheet metal has been cut, it is then bent and shaped using various tools and machines, including press brakes, rollers, and stamping machines. Sheet metal fabrication is an ideal technology for creating complex shapes and designs. With the right tools and techniques, sheet metal can be formed into a wide range of shapes, including curves, angles, and intricate patterns.

What is Sheet Metal Fabrication?

Sheet metal fabrication is extensive and thus difficult for some to understand. Their requirements are not clear, resulting in unrealistic expectations and requirements for the project. In addition, its machined raw materials are versatile, and it is entangled in which material can achieve the most desired shape. The following process of manufacturing metal parts involves multiple steps from start to finish.

●Creating Engineering Drawings

The first step in sheet metal fabrication is the design and engineering phase. This involves creating detailed drawings or 3D models of the desired product using computer-aided design (CAD) software. The design takes into account factors such as dimensions, tolerances, material selection, and end-use requirements.

●Manufacturability Analysis

Once the drawing is received by the engineer, it will be carefully checked to make sure it meets the requirements and specifications. Following DfM strategies, engineering analysis is performed, and engineers gain insight into developing designs for manufacturability. Once the manufacturability analysis is complete, there are final shop drawings with in-depth calculations of stress/strain levels and load limits. The information available therein will determine the sheet metal fabrication process. Finally, output the DFM report for customer reference.

●Prototype Development

Engineers perform a number of procedures to retain the component's shape once a sheet metal design model has been created. These processes include welding, cutting, bending, punching, and stamping. Surface treatments also contribute to the produced prototype's improved looks. It's crucial to complete these tasks sequentially. The integrity and quality of the finished product may be compromised if the process is rushed or if a stage is skipped.

●Prototype Testing

Clients examine the prototype after it is developed to make sure it satisfies their needs. Utilizing these components in actual environments may also be part of the testing. Additionally, users' reviews of the products might be included in the evaluation process.

●Full-Scale Production

Prototypes are received by the customer, tested, and prototypes that meet the required specifications go into mass production.

How Does Sheet Metal Fabrication Work?

The sheet metal fabrication procedures begin with removing materials from thin sheet metal stock placed on a flatbed and following programmed part patterns with cutting tools to make desired forms. A variety of subtractive machining technologies can be used to complete this job. According to the part geometry, a sheet metal punch, shear, laser, waterjet, or plasma can generate extra features such as internal holes and edge features. Material deformation is the second stage. After being cut, the pieces are routed to the press brake, where they are formed into the final geometries using a forming process such as bending. The final stage is to assemble sheet metal pieces or put them together with non-sheet metal components to form a complete product. Surface finishing operations are used in many instances.

Sheet Metal Prototyping to Production

Sheet metal fabrication is flexible for prototyping to mass production. The transition from sheet metal prototyping to full-scale production involves careful planning, precision manufacturing, and quality control measures to ensure consistent and reliable production of sheet metal components.

●Rapid Tooling:

The required tooling or molds are created using quick tooling techniques like 3D printing, CNC machining, or laser cutting. These methods enable the rapid and precise manufacture of tooling. Rapid tooling in sheet metal fabrication enables faster turnaround times for production while maintaining the required precision and quality. It is particularly beneficial for small to medium production runs or when there is a need for quick prototyping and iterative design improvements. By using rapid tooling techniques, manufacturers can accelerate the sheet metal fabrication process, reduce costs, and streamline the overall production workflow.

In sheet metal fabrication, the practice of swiftly making prototypes of sheet metal components to check and confirm their design, fit, and functionality is referred to as rapid prototyping. It entails speeding up the prototyping step by using a variety of fast prototyping methods that are specialized to sheet metal. Rapid prototyping in sheet metal fabrication speeds up the validation of design ideas while saving time and money over conventional prototyping techniques. It enables engineers and designers to quickly determine whether their designs are feasible, to make the necessary corrections, and to iterate quickly to improve the product. Manufacturers can expedite the production of high-quality sheet metal components, speed up the development process, and optimize designs by using sheet metal-specific rapid prototyping processes.

●Batch Production

In sheet metal fabrication, batch production refers to the sequential production of a set number of sheet metal components. Design and planning, material preparation, tool setup, and production runs are all parts of the process. Utilizing a variety of fabrication techniques, including cutting, bending, welding, and finishing, the sheet metal is formed, cut, and put together. As the same component is manufactured in a series, batch production has benefits including increased efficiency, cost-effectiveness, and consistent quality. It is appropriate for medium-volume manufacturing runs with predetermined component requirements. In the fabrication of sheet metal, batch production enables simplified manufacturing procedures and optimal resource use.

Sheet Metal Fabrication Standards

Our custom sheet metal fabrication services are ISO 2768-m compliant to assure part maneuvrability and precision of produced prototypes and parts.

Dimension Detail | Metric Units | Imperial Units |

Edge to edge, single surface | ±0.127 mm | ± 0.005 in. |

Edge to hole, single surface | ±0.127 mm | ± 0.005 in. |

Hole to hole, single surface | ±0.127 mm | ± 0.005 in. |

Bend to edge / hole, single surface | ±0.254 mm | ± 0.010 in. |

Edge to feature, multiple surface | ±0.762 mm | ± 0.010 in. |

Over formed part, multiple surface | ±0.762 mm | ± 0.030 in. |

Bend angle | ± 1° | |

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing. | ||

Common Types of Sheet Metal Fabrication Processes

●Sheet Metal Cutting

Sheet metal cutting is a fundamental process in sheet metal fabrication. It involves removing material from sheet metals to create the desired shape and size. When choosing a suitable cutting method for a sheet metal fabrication project, precision, the thickness of the metal, and the complexity of the parts design should be taken good consideration. There are several methods of cutting sheet metal, including manual methods, such as shearing and nibbling, as well as automated methods such as laser cutting, plasma cutting, and waterjet cutting.

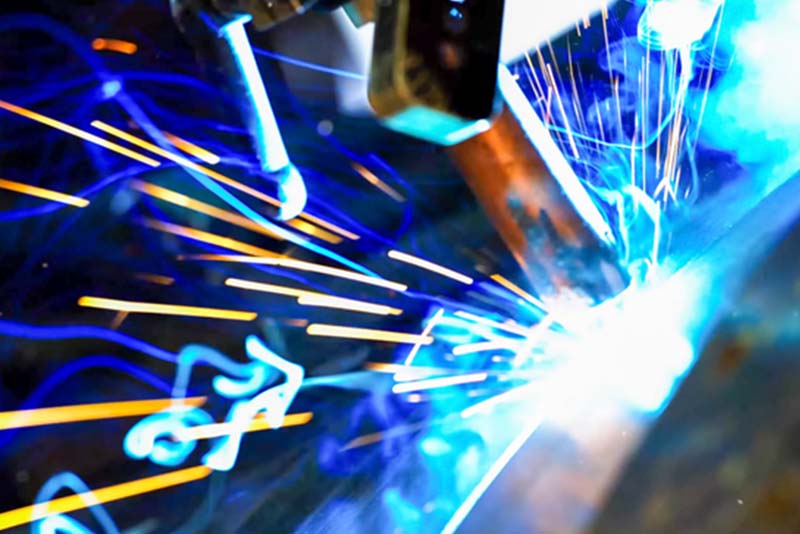

●Laser Cutting

Laser cutting is a highly precise and efficient method of cutting sheet metal. It uses a high-powered laser beam to melt and vaporize the metal along a predetermined path. Laser cutting is a popular choice in sheet metal fabrication due to its ability to produce precise cuts with smooth edges and minimal distortion. One of the advantages of laser cutting is its ability to produce precise cuts with minimal distortion. Laser cutting is capable of cutting through a wide range of materials and thicknesses, and it can be used to create intricate shapes and designs with high levels of accuracy and repeatability. Laser cutting is also a fast and efficient process. However, the initial cost of opening a laser-cutting machine can be high, and the ongoing maintenance and repair costs can also be significant.

●Plasma Cutting

Plasma cutting uses a plasma torch to cut through the metal. And it is an efficient way to produce fast and precise cuts through a wide range of materials and thicknesses. It is capable of cutting through metals like steel, aluminum, and stainless steel, as well as other materials such as copper, brass, and titanium. Additionally, the process is fast and efficient, especially for thicker materials. However, it may lead to rough edges and imprecise cuts, especially in thinner materials.

●Waterjet Cutting

Waterjet cutting is a technique that uses a high-pressure stream of water that is mixed with abrasive particles to cut through metal. This method is widely used in sheet metal fabrication because it is capable of producing precise cuts in various materials and thicknesses. One of the benefits of waterjet cutting is it makes precise cuts with minimal distortion. This method can cut through numerous materials, including metals, plastics, and composites. It is also a fast and efficient technology, especially for small to medium-sized production runs. However, it is also relatively higher than other cutting ways . And it can be noisy and result in water and abrasive debris, which must be properly managed to ensure worker safety and environmental compliance.

●Sheet Metal Bending

Sheet metal bending is the process of shaping a workpiece along a straight axis to form a specific angle or shape. This can be done manually or with specialized machines like press brakes or folding machines. Bending is versatile and can create a wide range of shapes, such as L-shaped brackets, U-shaped channels, and Z-shaped profiles. It can also be combined with other processes like cutting, punching, and welding to create complex assemblies. One advantage of bending is that it produces durable parts with minimal material waste. By bending a workpiece, a strong and rigid structure can be created without additional fasteners or welding. Bending is a fast and efficient process, especially for simple shapes, but precision can be affected by factors like metal thickness and composition, workpiece geometry, and machine capabilities. Additionally, spring back can occur, which is when the metal returns to its original shape after the bend is released. Specialized tooling and techniques can reduce spring back, but they can still impact the accuracy and consistency of the bend.

●Sheet Metal Punching

Sheet metal punching involves creating holes or shapes in a workpiece using a punch and die. Punching is versatile and capable of producing diverse shapes and sizes, including round and square holes, notches, and custom designs. This method creates precise cuts with minimal waste and can cut through various materials like metals, plastics, and composites. Punching is efficient and ideal for large production runs. Despite its benefits, punching has limitations. It can leave burrs and other imperfections on the edges, requiring additional finishing to achieve a smooth surface. Punching may be less effective for very thick or hard materials that need alternative cutting methods like laser or waterjet cutting.

●Sheet Metal Welding

Joining metal pieces together by heating them to their melting point and allowing them to fuse is welding. This technique can be used to join a variety of metal materials and thicknesses, ranging from simple sheet metal joints to complex assemblies made up of multiple components. Welding has several advantages, including its ability to produce strong and durable joints that can withstand significant stress and strain. It can also create nearly invisible joints, resulting in a clean and seamless appearance. For larger production runs, welding is a relatively fast and efficient process. However, welding does have some limitations. If the heat input is not carefully controlled, it can cause deformations and distortions in the metal. Weld spatter can also form, which can be challenging to remove and may require additional finishing operations.

●Assembly

The assembly stage marks the end of the metal fabrication process and involves the creation of intricate metal structures and components. To complete the assembly, a range of techniques are employed, such as mechanical fastening, welding, and gluing. Mechanical fastening involves the use of bolts, screws, or other fasteners to securely hold metal parts together. Welding, on the other hand, creates a permanent bond between the parts, making the final product strong and long-lasting. Adhesives are also used for both temporary and permanent assemblies, particularly for creating lightweight structures or in situations where welding is not feasible.

Finishing Options for Sheet Metal Fabrication

Choose from a variety of surface finishing choices to increase the corrosion resistance, appearance, and cleaning time of sheet metal manufacturing components and products.

Name | Description | Materials | Color | Texture | |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

| Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass | N/A | N/A Matte |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Material Selection for Sheet Metal Fabrication

Whatever the application and requirements of your sheet metal fabrication part, trust NOBLE to find the right sheet metal fabrication material. Some popular materials available for custom metal fabrication are outlined below.

●Aluminum

Commercially, aluminum is the most sought-after material for sheet metal manufacturing. Its popularity is due to its adaptive qualities and its high thermal conductivity and low resistance rates. Compared to steel—another common sheet metal material—aluminum is more cost-effective and has a higher rate of production. The material also generates the least amount of waste and can easily be reused.

Features | Info |

Subtypes | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc |

Process | CNC machining, injection molding, sheet metal fabrication |

Tolerance | With drawing: as low as ± 0.005 mm No drawing: ISO 2768 medium |

Applications | Light & economic, used from prototyping to production |

Finishing Options | Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

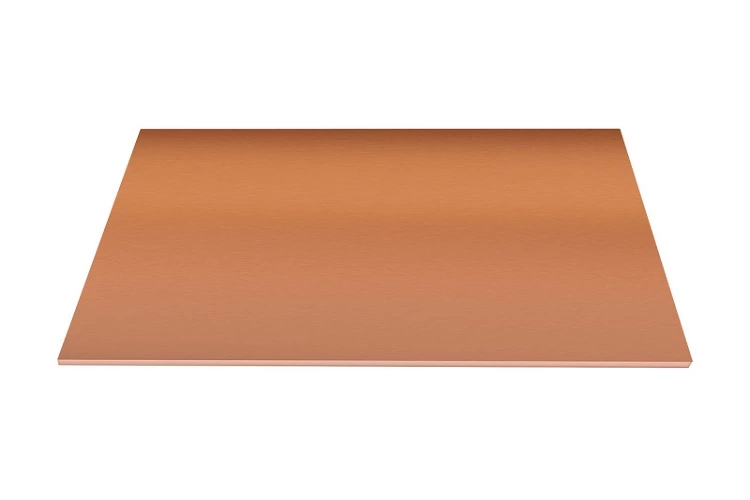

●Copper

Copper is a broadly used sheet metal fabrication material in many industries as it offers good malleability and ductility. Copper is also well suited for sheet metal fabrication because of its excellent heat conduction properties and electrical conductivity.

Features | Info |

Subtypes | 101, 110 |

Process | CNC machining, sheet metal fabrication |

Tolerance | ISO 2768 |

Applications | Bus bars, gaskets, wire connectors, and other electrical applications |

Finishing Options | Available as-machined,media blasted, or hand-polished |

●Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Features | Info |

Subtypes | 101, 110 |

Process | CNC machining, sheet metal fabrication |

Tolerance | ISO 2768 |

Applications | Bus bars, gaskets, wire connectors, and other electrical applications |

Finishing Options | Available as-machined,media blasted, or hand-polished |

●Steel

Steel offers a number of beneficial properties for industrial applications, including rigidity, longevity, heat resistance and corrosion resistance. Steel sheet metal is ideal for producing complex designs and parts that require extreme precision. Steel is also cost-efficient to work with and has excellent polishing properties.

Features | Info |

Subtypes | 4140, 4130, A514, 4340 |

Process | CNC machining, sheet metal fabrication |

Tolerance | With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium |

Applications | Fixtures and mounting plates; draft shafts, axles, torsion bars |

Finishing Options | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating |

●Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Features | Info |

Subtypes | 303, 304L, 316L, 410, 416, 440C, etc |

Process | CNC machining, sheet metal fabrication |

Tolerance | With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium |

Applications | Industrial applications, fittings, fasteners, cookware, medical devices |

Finishing Options | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating |

Major Types of Sheet Metal

Hot Rolled Steel

Hot-rolled steel is a type of steel that is produced through the hot-rolling process, where the steel is heated above its recrystallization temperature and passed through rollers to shape it into various forms. It is characterized by its malleability, strength, and cost-effectiveness. Hot-rolled steel is commonly used in construction, manufacturing, and automotive industries for structural components, pipes, and general applications. It offers good weldability and formability, making it a versatile choice for a wide range of applications requiring durable and easily workable steel.

Pre-Plated Steel

Pre-plated steel refers to a type of steel that has a protective coating applied to its surface before it is formed into a final product. The coating, typically consisting of zinc or other metals, provides enhanced corrosion resistance and durability to the steel. Pre-plated steel is commonly used in industries such as automotive, construction, and appliances, where protection against rust and corrosion is crucial. It offers the advantage of ready-to-use steel with a pre-applied protective coating, reducing the need for additional surface treatments and improving the longevity of the final product.

Carbon steel

Carbon steel is a widely used type of steel that primarily consists of iron and carbon. It is known for its strength, durability, and affordability, making it a popular choice in various industries. Carbon steel is versatile and can be easily fabricated into different shapes, making it suitable for applications such as construction, automotive, machinery, and infrastructure. It can be further enhanced through heat treatment and alloying to improve its mechanical properties. Carbon steel is valued for its high tensile strength and ability to withstand heavy loads, making it a reliable material in numerous industrial and commercial settings.

Galvanized steel

Galvanized steel is a type of steel that has been coated with a layer of zinc to provide protect corrosion. The galvanizing process involves immersing the steel in a bath of molten zinc, creating a durable and corrosion-resistant coating. Galvanized steel is widely used in industries such as construction, automotive, and manufacturing, where protection from rust and corrosion is essential. It offers excellent longevity, strength, and affordability, making it suitable for applications such as roofing, fencing, structural components, and outdoor equipment. Galvanized steel provides a reliable and cost-effective solution for projects requiring robust corrosion protection.

Stainless steel

You have a variety of stainless steel kinds to pick from. They might be stainless austenitic steel. These are non-magnetic metals having significant concentrations of nickel and chrome. Due to their formability and corrosion resistance, they are widely used. On the other hand, ferritic stainless is magnetic. They work well in applications that aren't structural or aesthetic. Martensitic stainless also produces items that are robust and corrosion-resistant.

Aluminum

Aluminium is a strong, lightweight metal with a wide range of uses. It also has great corrosion resistance. It has several uses in sectors like packaging, building, aerospace, and automobiles. Aluminium is a popular material for many goods, from aircraft parts to beverage cans, because of its strength, conductivity, and capacity to be recycled.

Copper/Brass

Copper is a versatile metal widely used for its excellent electrical conductivity, heat resistance, and corrosion resistance. It finds applications in electrical wiring, plumbing, electronics, roofing, and industrial machinery. Copper's durability, malleability, and ability to conduct heat and electricity make it a valuable material in numerous industries.

Benefits of Sheet Metal Fabrication

Sheet metal fabrication has several advantages, which make it a popular choice for diverse applications. These include simple brackets and enclosures, as well as complex structures and machinery.

1. Precision: Sheet metal fabrication allows for precise shaping and cutting of metal sheets, enabling the creation of complex geometries with high accuracy.

2. Lightweight: Sheet metal is a lightweight material, making it ideal for situations where weight is a crucial factor, such as in the aerospace and automotive industries.

3. Aesthetics: Sheet metal can be finished in various ways, such as painting, polishing, and powder coating, to enhance its appearance and provide a professional finish.

4. High-temperature resistance: Sheet metal can withstand high temperatures without losing its strength or shape, making it suitable for use in high-temperature applications such as furnaces and ovens.

5. Easy to work with: Sheet metal is a pliable material that can be easily cut, shaped, and welded. This makes it easy to work with and assemble.

6. Low maintenance: Sheet metal structures require minimal maintenance, which makes them a cost-effective option in the long run.

7. Compatibility with other materials: Sheet metal can be easily combined with other materials such as plastics, wood, and glass to create hybrid structures with unique properties.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is used in a variety of industries, whether for structural purposes, ornamental aspects, or functional components within other goods. Here are some prevalent applications of Sheet metal fabrication.

Automotive parts Sheet Metal Fabrication

Sheet metal fabrication is widely utilized in the automobile industry to produce car bodywork, structural components, engine parts, brackets, exhaust systems, and a variety of interior and exterior components.

Aerospace parts Sheet Metal Fabrication

Sheet metal fabrication is critical in the aerospace industry because it provides lightweight, strong, and precise components that contribute to an aircraft's overall performance, safety, and efficiency.

Such as wings, fuselages, frames, brackets, engine enclosures, and control surfaces.

Medical Equipment Sheet Metal Fabrication

Sheet metal fabrication provides durable, customizable, and functional components that contribute to the efficiency and effectiveness of medical devices and equipment. Such as cabinets, carts, trays, medical instrument casings, hospital beds, and diagnostic equipment.

Energy and Power Generation Sheet Metal Fabrication

Sheet metal fabrication is utilized in the energy sector for manufacturing components used in power generation plants, including turbine casings, heat exchangers, pipes, and structural supports.

Industrial Machinery Sheet Metal Fabrication

Sheet metal fabrication has several possibilities and advantages. Sheet metal fabrication delivers long-lasting and economical solutions for industrial equipment, structures, and operations, from manufacturing customized components to optimizing production processes. Common parts like frames, enclosures, panels, guards, brackets, and conveyor systems.

Electronics and Telecommunications Sheet Metal Fabrication

Sheet metal fabrication is used to make electronic enclosures, racks, cabinets, chassis, brackets, and panels used to house electronic devices, servers, networking equipment, and telecommunications infrastructure.

Why choose NOBLE Custom Sheet Metal Fabrication?

For a variety of industries, including automotive, aerospace, robotics, medical, and more, NOBLE is an industry leader in offering top-notch sheet metal fabrication services. No matter how difficult a client's project requirements are, our team of knowledgeable and experienced specialists is dedicated to providing them with the greatest results. Every project is completed with accuracy and precision thanks to our cutting-edge technology and tools. We provide a variety of sheet metal fabrication services, and our cutting-edge equipment can easily handle any project. No matter if you require a single prototype or big volumes of production, our business can offer you the best sheet metal fabrication options at reasonable costs. We are committed to providing the best outcomes on schedule and within budget.

●Quality and Accuracy Assurance

With certification ISO9001:2015 of ISO 9001-2015 and ISO13485-2016, we make investments in cutting-edge machinery and technology to deliver excellent custom sheet metal fabrication. Our facility is outfitted with cutting-edge equipment and tools, allowing us to complete complex fabrication procedures precisely and effectively. We are able to offer superior-quality products while streamlining production schedules and reducing errors because we stay current with the most recent developments in the field. The quality and precision of sheet metal parts we produce will exceed your expectations.

●Customization and Flexibility

The degree of customization and flexibility we provide is one of the main benefits of selecting our custom sheet metal fabrication service. We are aware that every project is different and can call for particular designs, measurements, or materials. In order to fully grasp the demands of each client, our staff consults with them frequently. We place a high priority on customization and make sure that the finished product complies with the client's exact requirements from concept creation to final output.

l Sheet Metal Engineering Support

NOBLE engineers provide 24/7 online engineering customer support for your custom sheet metal engineering and fabrication questions. This includes case-by-case advice to help you reduce costs early in the design phase.

●Customer Satisfaction

At NOBLE, we consider quality control to be a crucial step in the manufacture of custom sheet metal. Every stage of production is subject to strict quality standards and thorough inspection processes. This guarantees that the finished product is defect-free and satisfies the highest quality standards. Customer satisfaction is our top priority, and we work hard to go above and beyond expectations by offering dependable, long-lasting, and aesthetically pleasing sheet metal fabrication solutions. We stand out as a dependable option for custom sheet metal fabrication because of our dedication to quality control and client satisfaction.

Sheet Metal Fabrication FAQs

1. What is considered fabrication?

Fabrication is the production of products using a combination of typically standardized parts and one or more separate techniques. Steel fabrication, for example, entails producing metal structures using a range of techniques such as cutting, bending, and assembling.

2. What is fabrication material?

Fabrication materials are the raw materials or substances that are utilized in the fabrication process to build or construct a product or component. Depending on the nature of the fabrication process and the desired final product, the specific materials utilized can vary greatly. Common materials are Aluminum, copper, stainless steel, brass and steel.

3. What is the difference between sheet metal and forging?

Sheet metal fabrication is a versatile method of forming thin metal sheets that provide flexibility, precision, and lightweight components. Forging, on the other hand, is a hot working method that creates robust and durable metal components ideal for heavy-duty applications but with shape complexity restrictions.

4. What is sheet metal mainly used for?

Sheet metal is widely utilized because of its versatility, strength, and low cost. It is widely used in a variety of industries, including automotive, construction, aerospace, and electronics. Sheet metal is primarily employed in the manufacture of structural components, enclosures, and cabinets. It is used in the construction industry for roofing and cladding, and it is utilized in the automotive industry for body panels and structural parts. Sheet metal is also used in HVAC systems, electrical enclosures, and equipment manufacture. Furniture, medical equipment, and aircraft components are among its many applications. Overall, sheet metal is a versatile material that is used as a basic building component in a variety of sectors.

5. What are the three 3 types of metal fabrication?

Cutting, forming, and welding are three popular metal fabrication procedures. These techniques are further subdivided into sub-categories such as laser cutting and plasma cutting, forming methods such as bending and stretching, and welding techniques such as MIG and TIG welding.

6. What is basic metal fabrication?

Metal fabrication is the process of assembling, cutting, and bending metal to create metal structures. Punching metal using a metal fabrication tool to create holes, louvers, or other shapes. Using rotary cutters to remove material from metal is known as milling.

7. How are sheet metal parts made?

Forming, casting, molding, joining, and machining are examples of traditional metal manufacturing processes. In various sheet metal forming procedures, force is applied to a piece of sheet metal in order to plastically deform it into the desired shape while leaving no material behind.

8. What are sheet metal components?

Materials that are typically used. Almost all of the popular technical metals are also utilized as sheets. Carbon steel, stainless steel, copper, and aluminum are a few of them. The use and specifications of your product will determine which is best for you.

Related News

- NOBLE Participated in the COSMOPROF ASIA HONGKONG 11-22, 2023

- NOBLE Obtained Three Important Certificates Includ 11-08, 2023

EN

EN  AR

AR NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES ID

ID HU

HU TH

TH MS

MS