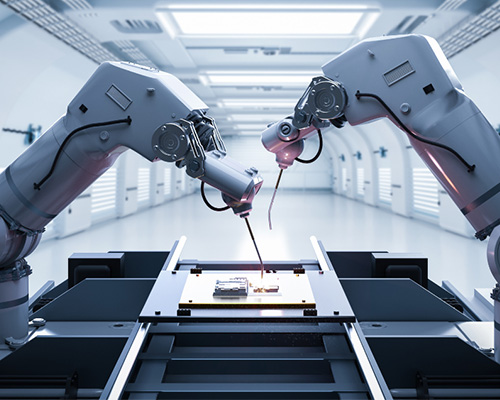

Rapid Prototyping and On-Demand Production for Automation Industry

As the automation industry continues to evolve and innovate, the need for rapid prototyping and on-demand production has become increasingly important. NOBLE rapid prototyping services allow you to quickly and easily create functional prototypes to test and refine your designs, allowing you to see and feel your design before moving into production. And on-demand services produce parts with a high level of accuracy and detail.

Rapid Prototyping & Parts Manufacturing for Automation Industry

NOBLE supports you from rapid prototyping to on-demand production. Produce higher quality parts in days at lower cost by streamlining the process.

●Advanced Equipment & Cost-Effective Price

●10+ years of Automation Parts Machining

●ISO 9001 & ISO13485 Certified Factory

●24/7 Engineering Support

●Professional DFM Report

Our Robust Manufacturing Capabilities for Automation Industry

NOBLE has been focusing on the automated production of excellent industrial components from simple automated parts for over ten years. Our team of engineers and designers can listen to customers' needs and ideas, complete complex and difficult automation projects, produce on-demand at cost-effective prices, launch new products faster, reduce risks, simplify production processes, and ensure the quality of aerospace components supplied by customers.

100+

CNC Machines

±0.001MM

Tolerances

50+

Materials

12+

Surface Finishes

Our Robust Automation Parts Machining Processes

NOBLE has 12 years of experience in the field of automated parts processing, from prototyping and design verification to functional testing and product release. A variety of processing techniques are available for you to choose from, and a professional engineering team assists you in optimizing the prototype design, selecting the most suitable technology to reduce costs and achieve rapid mass production.

CNC Machining Services

With precision 3-axis, 4-axis, and 5-axis CNC machining centers,fast and pricise cnc machining makes car parts wthin five days.

Learn More

Injection Molding Services

Custom Injection molding parts from prototypes to production parts. Professional engineering assessments and numerous materials and finishes are to be chosen from.

Learn More

Sheet Metal Fabrication Services

NOBLE's custom sheet metal prototyping services provide a fast and cost-effective solution to your project from low volume to mass production.

Learn More

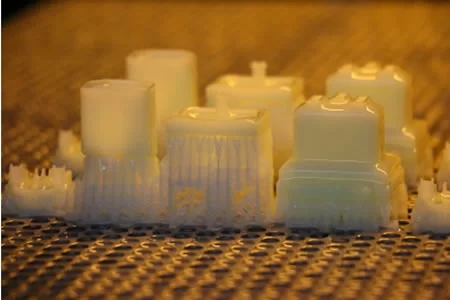

3D Printing Services

We successfully translate your concept into physical objects using a variety of secondary processes and sets of contemporary 3D printers.

Learn More

Vacuum Casting Services

NOBLE offers rapid vacuum casting for the manufacture of low-cost plastic parts. This fast prototyping method is similar to injection molding. However, the tools used for this fabrication are not very durable, making them ideal for small batches.

Learn More

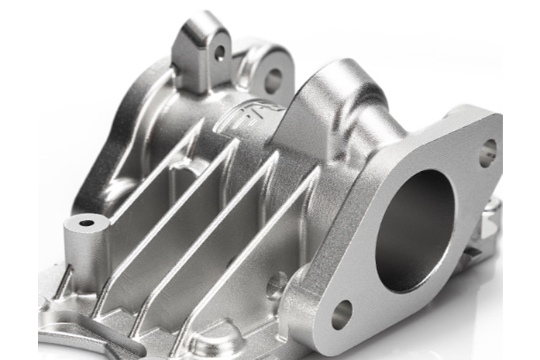

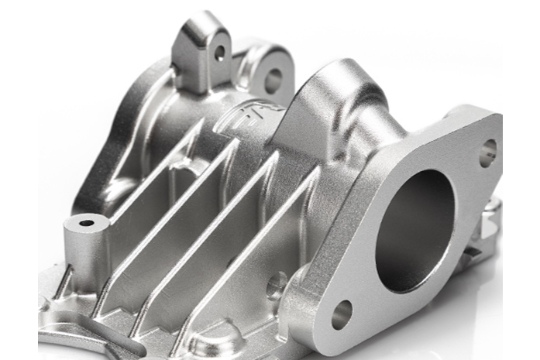

Die Casting Services

NOBLE has a rigorous die-casting process that guarantees we meet all your individual requirements. Our skilled engineering team and advanced equipment consistently produce durable prototypes and parts.

Learn More

Advantages of Rapid Prototyping for Automation Industry

Reduce Cost

One significant advantage of rapid prototyping is its capability to swiftly transform a product idea into a tangible product. Within a relatively short time frame, various product designs can be created, tested, and assessed. Upon finalization of a design, it can move on to the production stage without the potential of incurring expensive alterations in the future.

Product Iteration

Rapid prototyping could help industry experts swiftly produce working models of a new part design. It also enables greater product customization to satisfy specific requirements in comparison to conventional manufacturing processes, which impose more stringent design limits.

Cater to Market

Fast prototyping could alter the way parts enter the supply chain. Industry professionals can utilize this method to aid in low to medium-production runs, minimize material waste, and decrease inventory costs while satisfying fluctuating market demand.

Quality Assurance

Manufacturers may create and develop parts that are safer, cleaner, and lighter thanks to rapid prototyping. They can compare many designs before determining which is the most effective and efficient because the process has shorter design-to-delivery times than alternative techniques.

Prototyping and Production Solutions for Automation Industry

For more than ten years, NOBLE has been catering to the automation industry by offering efficient rapid prototyping and custom parts services. We provide dependable solutions for new product development, ensuring rigorous quality testing to deliver automation parts that exceed industry standards. Our on-demand production meets your manufacturing goals.

●Prototyping

During the early stages of automotive product development, prototypes play a crucial role in validating designs, making necessary modifications, and selecting suitable materials for automotive components. At NOBLE, we offer technical support throughout your project, ensuring reliable solutions for new product development and manufacturing parts that surpass industry standards, meeting your manufacturing requirements.

↓

●Engineering Validation and Testing (EVT)

Enter the engineering verification and testing phase, where you can verify that the functional characteristics of the prototype meet the standard requirements. NOBLE provides 24/7 design and engineering support to give you suitable advice to produce the best product for you at the most reasonable price.

↓

●Design Validation and Testing (DVT)

At this point, NOBLE chooses the best material from a variety of materials to design a finish option that satisfies your particular design needs. Durable, high-quality coatings give parts aesthetically pleasing finishes that can withstand market testing.

↓

●Production Validation and Testing (PVT)

PVT is the last phase before mass production and it uses sophisticated quality control and manufacturing tools to ready designs for full production. To guarantee optimal production, we'll consider your suggestions and give you the opportunity to make any final adjustments to your model.

↓

●Mass Production (MP)

This stage involves the mass production of end-use parts, with a focus on ensuring rapid delivery and precise quality .NOBLE provides meticulous inspections to control quality, secondary machining to meet optimal surface requirements, and precision machined parts that always meet tight tolerances.

Materials for Automation Parts Machining

ALuminum:

Aluminum has an excellent strength-to-weight ratio, making it ideal for producing lightweight automotive parts. This metal has several beneficial properties, including stiffness, corrosion resistance, ductility, and high machinability. Aluminum is ideal for making engine blocks, intake manifolds, lamps, wheels, cylinder heads, etc.

Aluminum | |

Price | $ |

Lead Time | 3 days |

Tolerances | ±0.01mm |

Max part size | 200 x 80 x 100 cm |

Titanium:

Titanium is another metal with extensive use in the automobile industry. This metal has excellent resistance to chemicals and corrosion. It also has an excellent strength-to-weight ratio and resistance to temperature extremes. Titanium has applications in automobile brake calipers, tire rims, engine valves, and other mechanical parts.

Titanium | |

Wall Thickness | 0.75 mm |

Lead Time | 3 days |

Tolerances | ±0.01mm |

Max part size | 200 x 80 x 100 cm |

Steel:

Steel is another metal with application in the production of modern-day automobile parts. This metal is durable and efficient in performance. It also facilitates the production of high-quality parts. It is resistant to corrosion, lightweight, and results in the production of aesthetically pleasing parts. This metal has applications in the production of car brakes, engines, exhaust systems, wheels, etc.

Steel | |

Wall Thickness | 0.75 mm |

Lead Time | 3 days |

Tolerances | ±0.01mm |

| Max part size | 200 x 80 x 100 cm |

Copper:

Copper plays a huge role in comfort, efficiency, and safety in the automotive industry. It is an excellent conductor of electricity, highly ductile, and malleable. It has application in most of the vehicle’s electronic components, including vehicle’s wire harness, radiator, starter motor, alternator, and brake tubes.

Copper | |

Wall Thickness | 0.75 mm |

Lead Time | 3 days |

Tolerances | ±0.01mm |

| Max part size | 200 x 80 x 100 cm |

Magnesium:

Magnesium is lightweight and has excellent castability and high specific strength, which gives it application in the automotive industry. Magnesium has applications in producing engine blocks, gearboxes, clutch housings, wheels and engine cradles, and oil pans.

Magnesium | |

Wall Thickness | 0.75 mm |

Lead Time | 3 days |

Tolerances | ±0.01mm |

| Max part size | 200 x 80 x 100 cm |

Thermoplastics:

A variety of thermoplastic materials could be used for robotics, including HDPE, Polypropylene, Acrylic, Polycarbonate, PPS, ABS, and PC-ABS. Excellent characteristics of these thermoplastics include great impact resistance and the capacity to withstand high temperatures. PPS. For instance, it has exceptional temperature tolerance, stiffness resistance, and dimensional stability.

Surface Finishes for Automation Parts Machining

With a wide selection of surface finishes, NOBLE can help improve the surface qualities of your products. Surface finishes applied to your customized parts aim at improving their appearance, surface hardness, and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

Name | Description | Materials | Color | Texture | |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

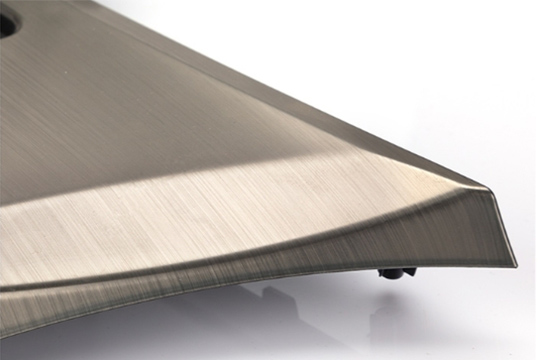

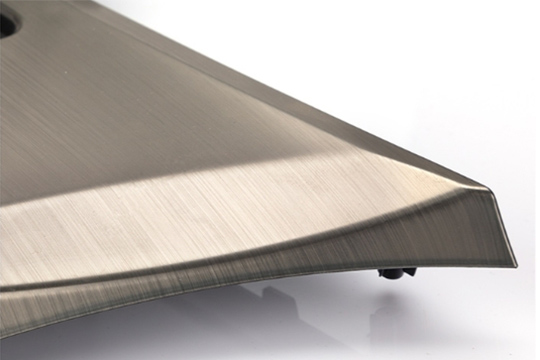

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Surface Finishes for Automation Parts Machining

With a wide selection of surface finishes, NOBLE can help improve the surface qualities of your products. Surface finishes applied to your customized parts aim at improving their appearance, surface hardness, and roughness, chemical and corrosion resistance, etc.

| |

| Name | Anodizing |

| Description | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. |

| Materials | Aluminum |

| Color | Clear, black, grey, red, blue, gold. |

| Texture | Smooth, matte finish |

| |

| Name | Powder Coating |

| Description | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. |

| Materials | Aluminum, Stainless Steel, Steel |

| Color | Black, any RAL code or Pantone number |

| Texture | Gloss or semi-gloss |

| |

| Name | Electroplating |

| Description | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. |

| Materials | Aluminum, steel, Stainless Steel |

| Color | N/A |

| Texture | Smooth, Glossy finish |

| |

| Name | Polishing |

| Description | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. |

| Materials | Aluminum, Brass, Stainless Steel, Steel |

| Color | N/A |

| Texture | Glossy |

| |

| Name | Brushing |

| Description | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. |

| Materials | ABS, Aluminum, Brass, Stainless Steel, Steel |

| Color | N/A |

| Texture | Satin |

Why Choose Us for Automation Parts Manufacturing

Industry-standard automation part prototypes and production are our areas of expertise at NOBLE. Regardless of complexity, we deliver high-quality products by combining our production and technical know-how with cutting-edge technology. We also make sure that parts endure the test of time while assisting you in achieving your production targets and speeding up the creation of new automation products.

Robust Manufacturing Capabilities

NOBLE has strong and reliable manufacturing capabilities that offer flexibility in terms of materials and surface finishes. We are capable of handling both small and large production runs, providing a one-stop service for any project needs. The manufacturing capacity is limitless, guaranteeing that each automobile item is of the highest quality, meets all dimensional requirements, and performs admirable.

Economical Price

We can offer you the lowest price in the same quality. Strictly control the machining and finish treatment quality, what you will get is what you designed.

On-Demand Customization

We help with design your desired part size, material, and finish to your specifications. Regardless of quantity, we could develop and customize so you can adapt to the market faster and stay ahead of the competition.

Tight Tolerances

We use advanced processing equipment and rich experience in auto parts machining to meet the manufacturing tolerance of ±0.001mm auto prototypes, assist customers in optimizing designs, choose appropriate processes, reduce costs, and achieve rapid mass production.

Quality Assurance

Manufacturers may create and develop parts that are safer, cleaner, and lighter thanks to rapid prototyping. They can compare many designs before determining which is the most effective and efficient because the process has shorter design-to-delivery times than alternative techniques.

Short Cycle

With NOBLE, you can get a quote in minutes and parts in days, reducing cycle time by up to 40%. The perfect combination of advanced technology and rich technical experience helps us provide quality robot parts with faster lead times.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Upload Your Design

Just simply upload your CAD files and submit RFQs with clear information online.

Receive Design Analysis

We'll send you design for manufacturability analysis and transparent pricing.

Start Manufacturing

Our experts will produce your parts with the required technologies and materials.

Receive Your Parts

Your parts will be delivered to your door directly with stringent deadlines.

Tusted by Automation Engineers and Designers of the Fortune 500 Companies

In the current industrial landscape, competition is fierce. However, top automation companies rely on us to help them maintain their edge. NOBLE professional engineer team and complete management process make industrial operations more efficient. We always strive to exceed expectations and provide quick, cost-effective solutions to meet the ever-evolving demands of the automation industry.

●Heavy Machinery Plant Industrial robotics

●Farm equipment Company

●Industrial tractors and vehicles Manufacturers

●Industrial robotics

●Industrial products and service

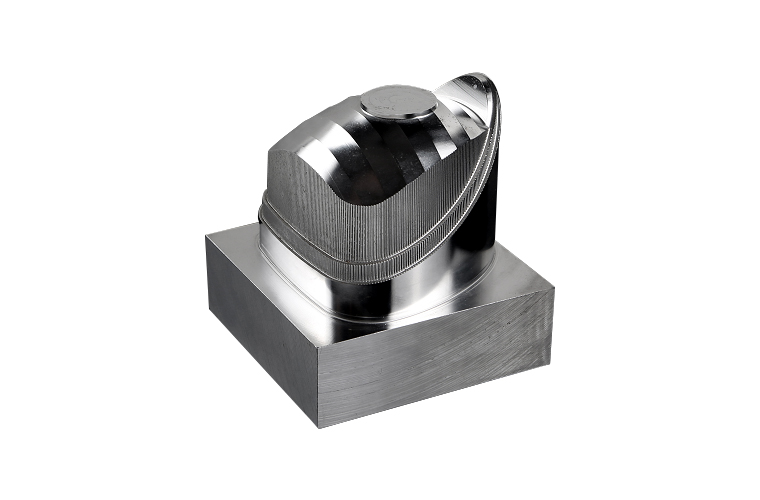

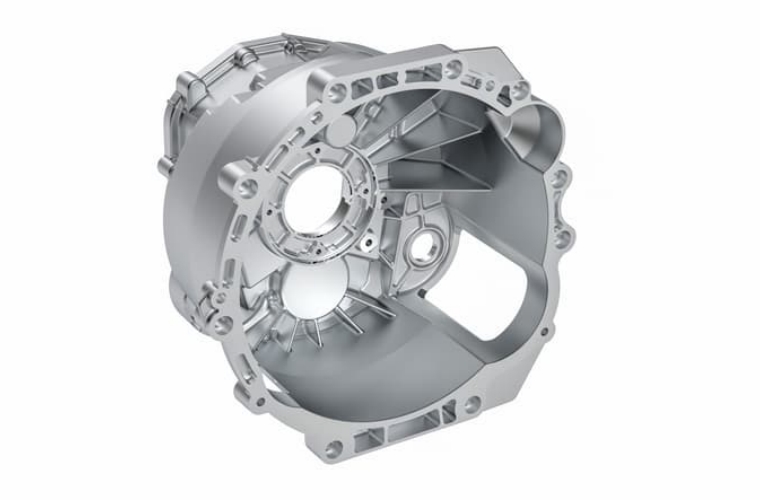

Case Display of Automation Parts Machining

We custom high-quality parts for industrial automation from prototyping to volume. Provide professional and perfect service at the most favorable price. Assist customers to optimize designs, choose the right process, reduce costs, and achieve rapid mass production. The following demonstrates the high-precision automation components we process for our customers to meet industry performance and safety standards.

See What Our Customers Say About Us

Our team of engineers has years of experience and a proven track record of success, making us experts in handling even the most complex automation project and earning reputations from our customers.

William —— Lead Engineer

Your custom parts services are simply outstanding. From start to finish, your team was professional, courteous, and attentive to my needs. The parts were delivered on time and exceeded my expectations in terms of quality and precision. I will definitely be using your services again in the future!

James —— Princile Engineer

Thanks for your top-notch custom parts services. Thanks to your skilled engineers and technicians who are dedicated to delivering exceptional results. The parts were of the highest quality and fit perfectly. I'm thrilled with the outcome, and I wouldn't hesitate to use your services again in the future.

Michael —— Director

I recently looked for custom parts services for my new project. My friends recommended NOBLE. The result and time were perfect. I highly recommend their services to anyone in need of custom automotive parts!

David —— Vive President

We received exceptional service from NOBLE. Danna assisted us with great patience and understanding, ensuring that the product we received was exactly what we had requested. The final product works amazingly, and we are especially pleased with the attention to detail that was given to our specific requests. Overall, we are very satisfied with the good-looking product and the great service provided.

Applications of Automation Parts

Provide high-quality prototyping and manufacturing services for your industrial needs, advanced technology and professional teams, and customize high-quality parts for many partners in the automation industry.

●Automatic control equipment

●Industrial robots

●Elevators and escalators

●Automatic Dispenser

●Automatic locking screw machine

●Agricultural custom machinery

●Steel rolling mills

Automation Parts Machining FAQs

- Q

What is automation parts machining?

AAutomation parts machining is the process of using computer-controlled machines and robotics to manufacture parts or components to precise specifications. This process involves programming the machines to perform specific tasks, such as cutting, drilling, and finishing, to create the finished part.

- Q

What materials are used in automation parts machining?

AAutomation parts can be machined from a variety of materials, including metals such as aluminum, steel, and titanium, as well as plastics and composites. The choice of material depends on the specific requirements of the part, including strength, durability, and weight.

- Q

What types of machines are used in automation parts machining?

AAutomation parts machining involves the use of a variety of machine tools, including lathes, milling machines, drill presses, and grinding machines. These machines are computer-controlled and can be programmed to produce parts with a high degree of precision and accuracy.

- Q

What are the five fundamental components of an automated system?

AAccording to experts, each subsystem comprises five basic components, which are the action element, sensing mechanism, control element, decision element, and program. The action element is responsible for providing energy to accomplish the task or goal in an automated system.

- Q

How can I ensure that my automation parts are machined to the required specifications?

ATo ensure that your automation parts are machined to the required specifications, it's important to work with a trusted and experienced machining service provider. Look for a provider with a proven track record of success, and who invests in the latest technology and equipment to ensure the highest level of precision and accuracy. Additionally, communication and collaboration between the customer and the service provider are key to ensuring that the finished parts meet the customer's requirements.

EN

EN  AR

AR NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES ID

ID HU

HU TH

TH MS

MS