| Name | Description | |

|

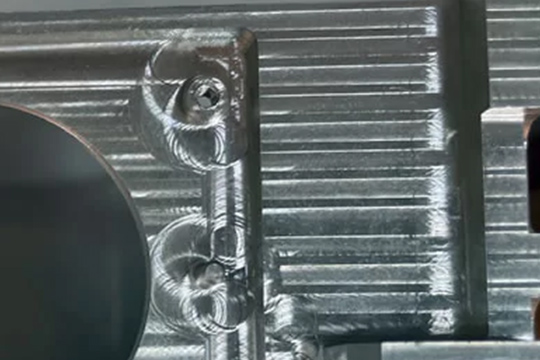

As Machined |

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin). |

|

Band Blasting |

Band blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts. |

|

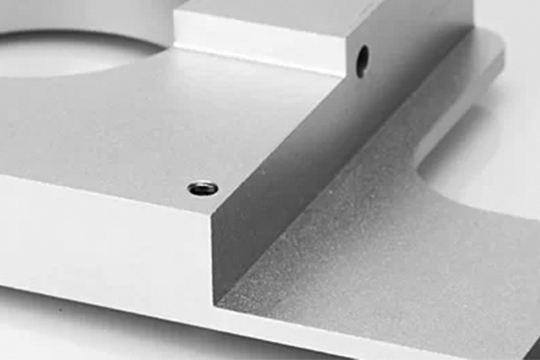

Anodizing |

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming. |

|

Electroplating |

Electroplating reduces metal cations in the electrolyte solution, producing a metallic coating on a metal surface. This process can be used for purposes of corrosion and wear resistance, as well as for decorative purposes. |

|

Polishing |

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra0.1 for a cleaner surface. |

|

Powder coating |

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down. |

|

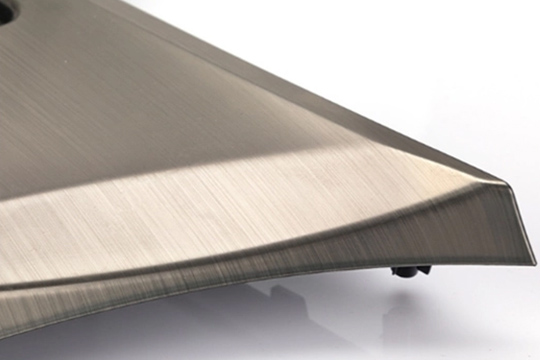

Brushing |

Our brushing technique uses abrasive belts over the material to create diverse patterns that match the parts’ structure and color. |

|

Painting |

Painting involves Spray droplets can be dispersed uniformly or in fine amounts to cover a wide surface area and bring out greater color to the part. |

|

Black Anodized |

Adding layers to metallic surfaces like steel, our black anodized technique improves appearance while maintaining durability. |

|

Alodine |

We use chromate conversion coating or alodine to protect aluminum and other materials from corrosive elements, usually done before priming and painting parts. |

|

Laser Carving |

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts. |

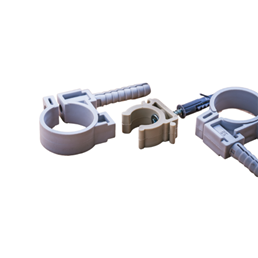

Introduction to Polyethylene

Polyethylene is the simplest polymer organic compound and the most widely used polymer material in the world. Polyethylene is polymerized from ethylene. Polyethylene is odorless, non-toxic, feels like wax, has excellent low-temperature resistance (minimum operating temperature can reach -100~-70°C), has good chemical stability, and can withstand most acid and alkali erosion (not resistant to oxidation) nature acid). Insoluble in common solvents at room temperature, low water absorption, and excellent electrical insulation. It is also sensitive to environmental stress (chemical and mechanical action), and its heat aging resistance is poorer than the chemical structure and processing of polymers. Polyethylene can be processed by general thermoplastic molding methods.

Information of Polyethylene

Polypropylene is a common materials for parts machining and manufacturing,below is some common information about Polypropylene.

| Features | Info |

Color | White, black |

| Process | CNC machining, injection molding |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Piping, Packaging |

| Price | $$$ |

Material Properties

There are common Subtypes of Polyethylene.

Subtypes | Ultimate tensile strength |

Tensile Strength

| Elongation at Break | Hardness | Maximum Temp |

HDPE | 22.1 – 31 MPa | 26.2 – 31 MPa | 500 – 700 % | 7.9 – 9.9 HV | 113 – 129 °C |

UHMWPE | 38.6 – 48.3 MPa | 21.4 – 27.6 MPa | 200 – 500 % | 3.4 – 8.3 HV | 80 – 110 °C |

Surface Finishes for Your Choosing

NOBLE has more than ten years of experience in surface treatment and excellent engineers, who are proficient in surface treatment of plastics, metals, and composite materials, and can turn your dream prototype or parts into reality.

EN

EN  AR

AR NL

NL FI

FI FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES ID

ID HU

HU TH

TH MS

MS